Ultrasonic Sensors for Production Lines

Migatron ultrasonic sensors provide non-contact sensing on production lines. Designed for industrial automation, ultrasonic sensors are well suited for detecting, measuring, and monitoring products.

From high-speed counting to robotic material handling, Migatron ultrasonic sensors help manufacturers improve production line reliability, reduce maintenance, and maintain consistent performance across systems like conveyors.

Contact Us to discuss your production line.

Applications in Industrial Automation

When selecting ultrasonic sensors for production lines or industrial automation, consider:

- Target size, material, and surface condition

- Required sensing range and response time

- Environmental conditions such as dust or moisture

Migatron partners with OEMs and system integrators to apply proven ultrasonic sensing solutions and develop custom configurations tailored to industrial automation requirements. Here are just a few of the many ways our sensors have been used in production lines.

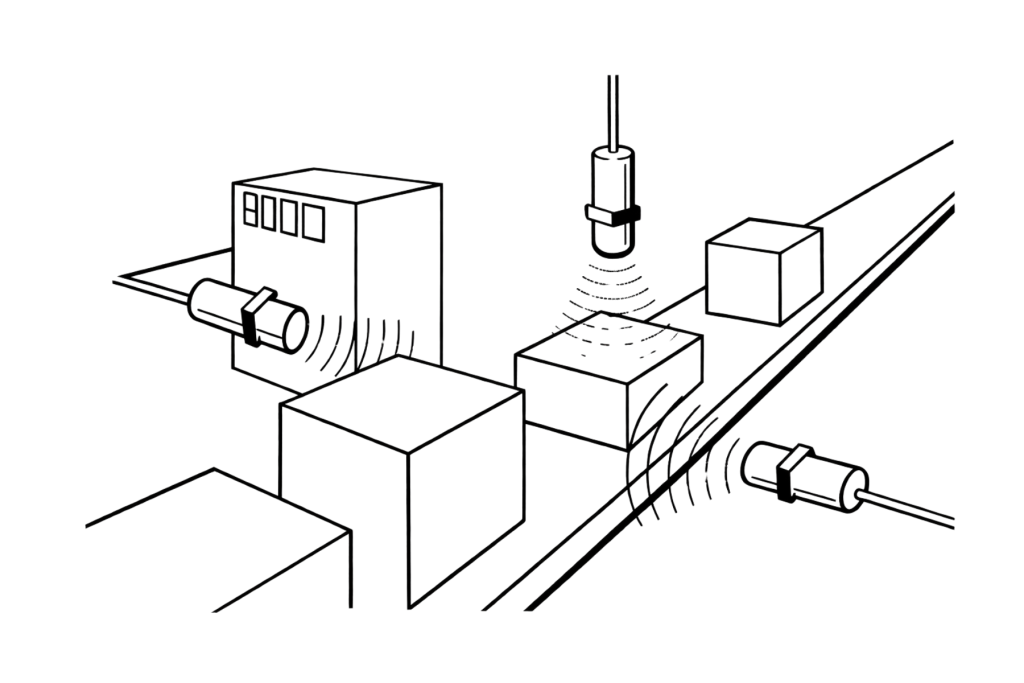

Box Sorting

Short-range ultrasonic proximity sensors are ideal for detecting box presence and spacing before diverters or gates. These sensors provide fast response and reliable detection regardless of object color, labels, or surface condition.

Recommended sensor:

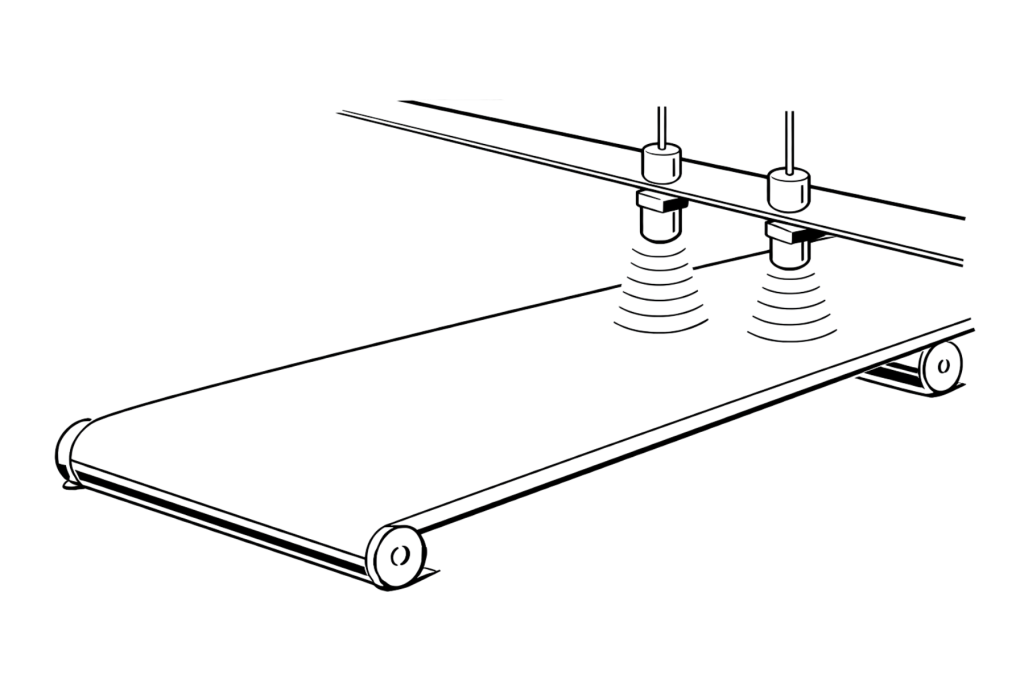

Conveyor Belt Alignment

The RPS-429A-IS provides continuous distance feedback to monitor conveyor belt position and edge drift. Its analog output supports closed-loop alignment control in industrial environments where reliability and hazardous-area approvals are required, such as mining.

Recommended sensor:

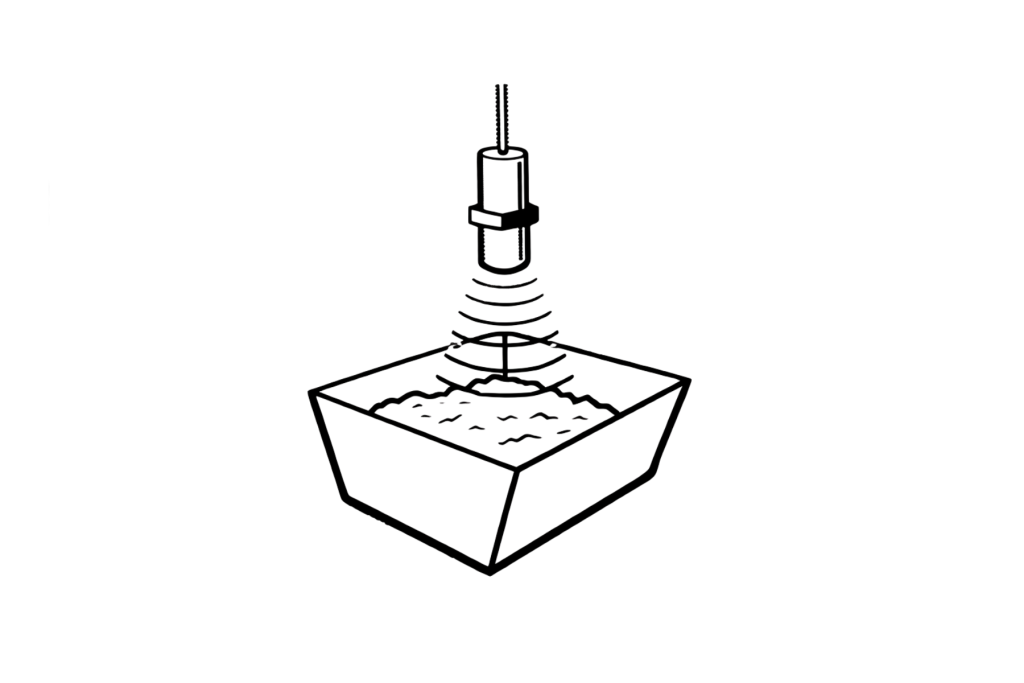

Hopper Level Detection

The RPS-150A is designed for non-contact level measurement in hoppers and bins. It provides stable level feedback on powders, granules, and bulk solids where contact-based sensors are prone to buildup or mechanical wear.

Recommended sensor:

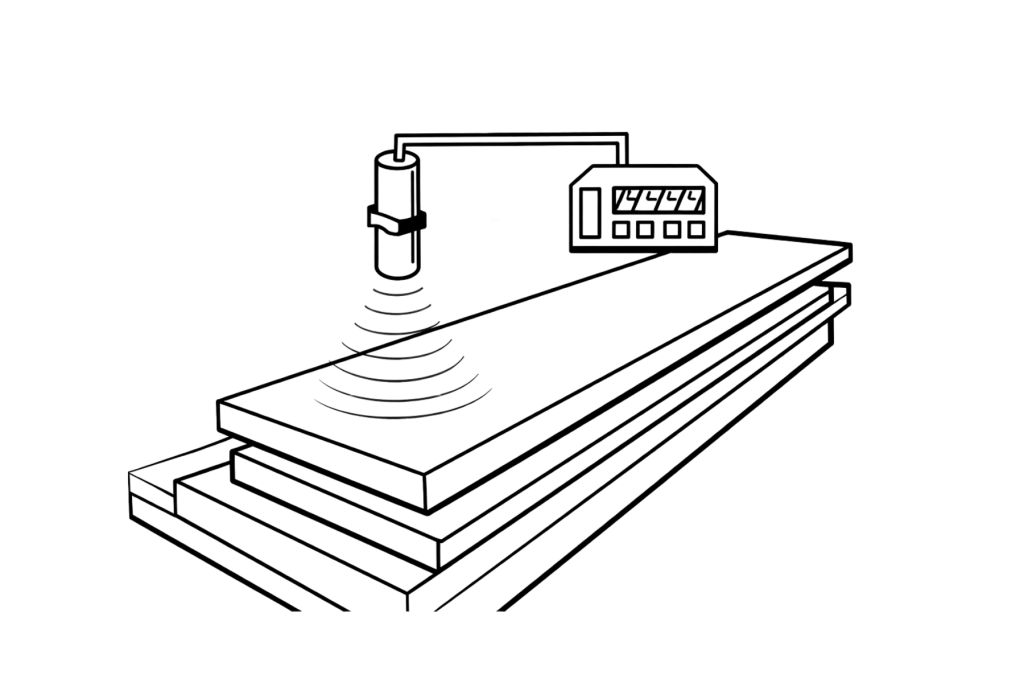

Stack Height Measurement

The RPS-409A-IS2 measures stack height on pallets or staged products using distance-based ultrasonic sensing. Intrinsically safe model allows use in regulated environments while maintaining accurate, repeatable measurements.

Recommended sensor:

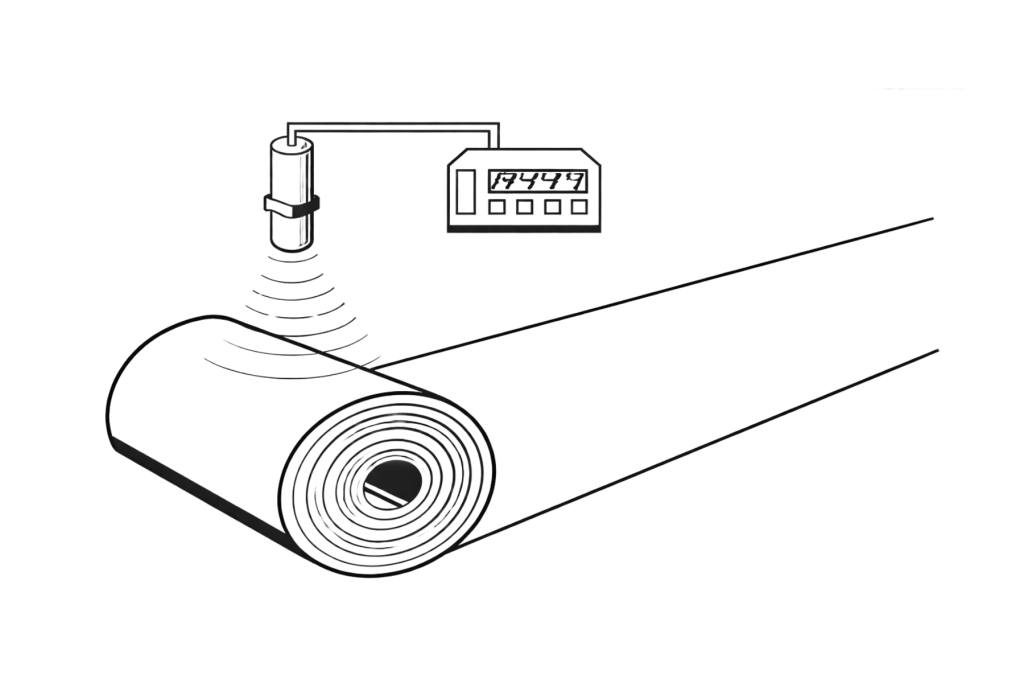

Roll Diameter Monitoring

By measuring distance to the roll surface, ultrasonic sensors calculate roll diameter in real time. This data is commonly used for unwind and rewind control, speed regulation, and material changeover timing.

Recommended sensor:

Sensors Designed and Manufactured in the USA

Migatron ultrasonic sensors are designed and manufactured in the United States. Our sensors are built for long-term use in industrial automation, conveyor systems, and production line environments.

Migatron maintains an ISO 9001, ATEX, and IECEx certified quality management system, ensuring controlled manufacturing processes, traceability, and compliance with international hazardous area standards.

Talk to an Applications Engineer

For new equipment builds, Migatron engineers collaborate with OEMs to select or customize ultrasonic sensors that meet application, performance, and integration requirements.

Contact us to discuss your design or get a quote.

Find a Sensor that Fits Your Production Line

-

RPS-401A and RPS-426A Analog Ultrasonic Sensor

$572.00 – $1,078.00Price range: $572.00 through $1,078.00 This product has multiple variants. The options may be chosen on the product page -

RPS-150 Wide Beam Ultrasonic Sensor

-

LCU-40APW Compact Ultrasonic Sensor