Ultrasonic Proximity Sensors for Automation

Material Handling Ultrasonic Sensors

Ultrasonic sensors play a critical role in manufacturing by enabling automation across the production floor. From conveyor lines to material handling systems, these non-contact sensors offer reliable detection, measurement, and control in challenging industrial environments.

Whether you need sensors for packaging machines or a sensor for part positioning, Migatron offers the best non-contact sensors for factory automation. Our non-contact sensors ensure that even irregular or transparent surfaces can be reliably detected, eliminating common production bottlenecks.

Ultrasonic Sensor Applications in Manufacturing

Conveyor Belt Object Detection

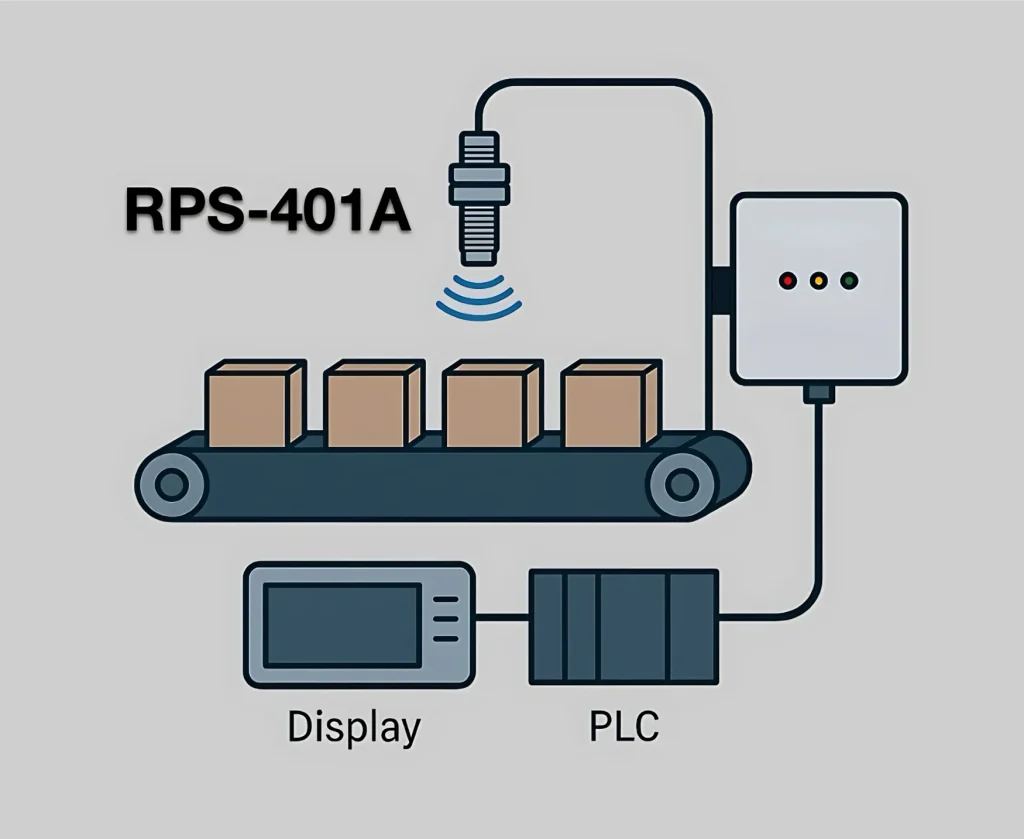

Featured Ultrasonic Sensor: RPS-401A

In manufacturing, automation sensors for conveyor systems play a vital role in monitoring materials throughout the production line. Preventing product accumulation is essential to avoid equipment strain and reduce downtime.

Why RPS-401A

- Compact design fits easily into tight conveyor spaces.

- Calibrated short range ultrasonic sensor ideal for low-profile material monitoring.

- A narrow sensing beam offers precise detection in confined or cluttered environments.

How It Works

- The RPS-401A Ultrasonic Sensor is mounted above the conveyor belt.

- It emits ultrasonic pulses to measure the height of materials on the belt in real time.

- Adjust conveyor speed

- Trigger alarms or shutoffs in overload conditions

Robot Guidance Sensor

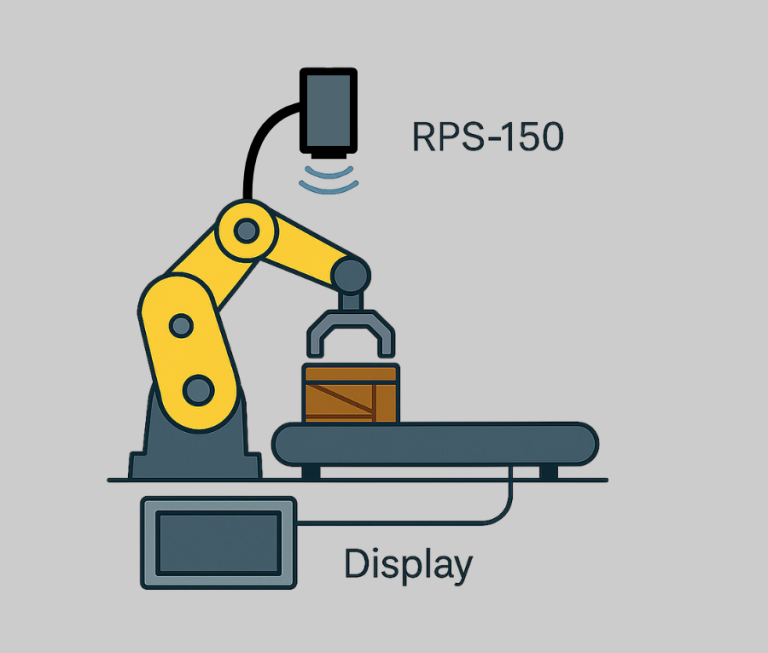

Featured Ultrasonic Sensor: RPS-150

How It Works:

- Emits a broad ultrasonic beam to detect objects within an adjustable range.

- Triggers solid-state relay outputs based on part presence or absence.

Why RPS-150

- Adjustable sensing range: 2″–40″ or 5″–80″ options available.

- A wide beam is ideal for detecting off-center or irregular targets.

- Solid-state relay outputs that are easy to integrate with PLCs or control systems

Ultrasonic Sensors for Original Equipment Manufacturers

Case Studies: Migatron Ultrasonic Sensors in Manufacturing

See how ultrasonic sensors are used in automation equipment based on these case studies.

- A manufacturer needs to know the diameter of finished rolls of paper products so they can be packaged.

- They need a non-contact sensor that would not be affected by changing target surfaces or colors.

- The customer was having problems with the photocells on their conveyor lines.

- They need a hazardous location sensor that can withstand a hostile environment.