About Ultrasonics

Understanding Ultrasonic Sensor Technology

Non-contact measurement for industrial level, distance, and presence detection

Ultrasonic sensors measure distance without contacting the target. By transmitting high-frequency sound waves and analyzing the returned echo, ultrasonic sensing provides a reliable, low-maintenance solution for level measurement, ranging, and object detection across a wide range of industrial environments. Migatron ultrasonic sensors are used globally by OEMs for liquid level monitoring, bulk material detection, proximity sensing, and distance measurement in applications where durability and simplicity matter.

How Ultrasonic Sensors Work

Ultrasonic sensors operate using a principle known as time-of-flight (TOF). The sensor emits a short ultrasonic pulse toward a target. That pulse reflects off the target surface and returns to the sensor. The elapsed time between transmission and reception is directly proportional to distance.

Migatron ultrasonic sensors continuously monitor this time-of-flight value and convert it into a usable output signal. Depending on the sensor model, whether its a Proximity Sensor or Analog Proximity sensor, this output may be:

- Analog current, typically 4–20 mA

- Analog voltage, such as 0–10 V or 1–5 V

- Discrete on/off switching outputs

Time-of-flight is based on the speed of sound, which changes with air temperature. Because ultrasonic sensors measure sound traveling through air, temperature compensation can be used to maintain accuracy. Migatron’s RPS-409A, RPS-429A, and RPS-4000 product lines incorporate temperature compensation to account for changes in the speed of sound caused by ambient temperature variations, ensuring stable measurement across the specified operating temperature range.

Two Types of Ultrasonic Sensors

Proximity Sensors

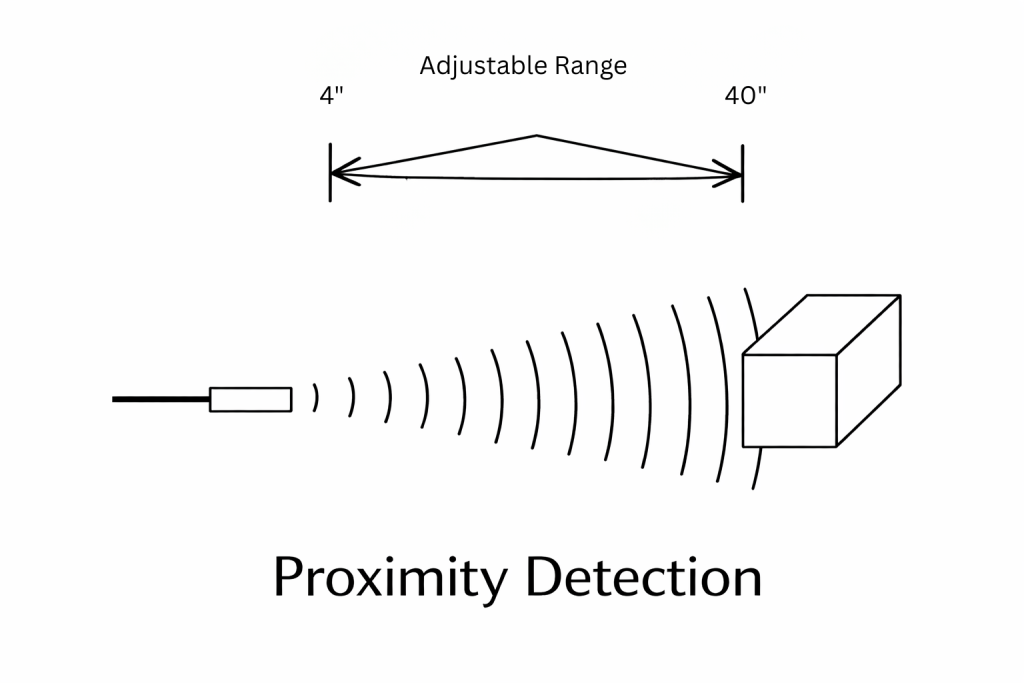

Proximity ultrasonic sensors are designed to detect the presence or absence of an object within a preset range. In the example below the maximum range can be adjusted from 4 to 40 inches.

An object passing anywhere within the preset range will be detected and generate an output signal. The detect point is independent of target size, material, or degree of reflectivity, provided the target reflects sufficient ultrasonic energy back to the sensor.

Key characteristics of proximity detection:

- Discrete on/off output

- Detection occurs anywhere within the defined range

- Target material, color, and transparency do not affect detection

- Commonly used for presence detection, limit sensing, and object confirmation

This sensor type is well suited for applications where knowing that something is present is more important than knowing its exact position. This also applies to single point level detection for liquids and bulk materials.

Analog Proximity Sensors

Or ranging ultrasonic sensors continuously measure the precise distance between the sensor and the target.

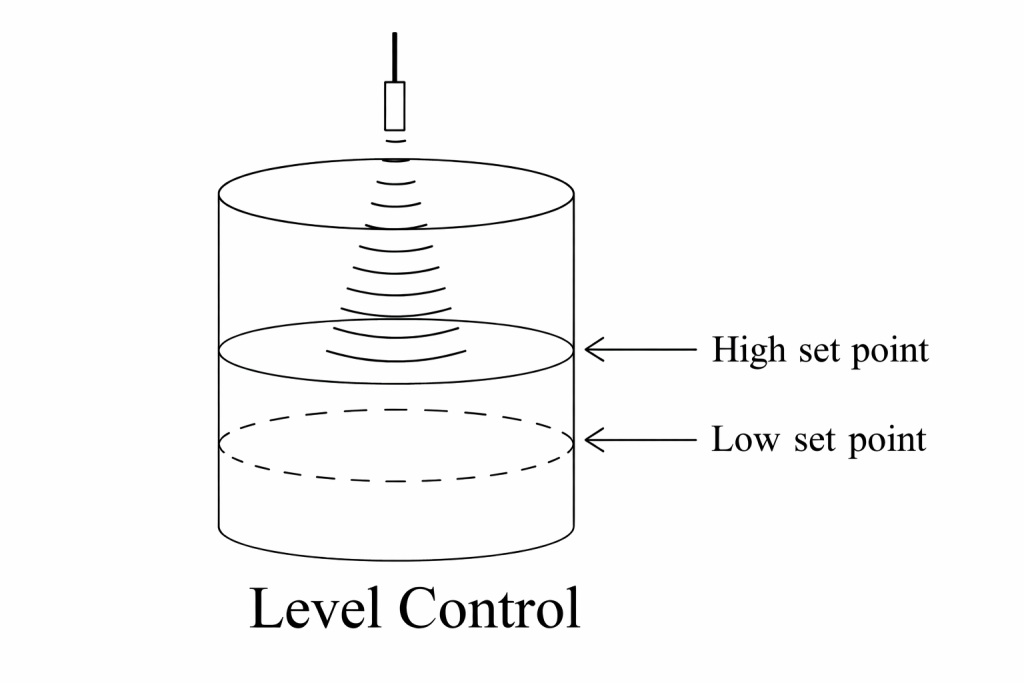

Distance is calculated by measuring the time interval between transmitted and received bursts of ultrasonic sound. As the target moves toward or away from the sensor, the time-of-flight changes. This change is continuously calculated and converted into an analog output signal.

In the example shown, the target is given a range with a high set point down to a low set point. The sensor continuously updates the output to reflect this distance change as the target moves up and down through that range.

Key characteristics of ranging measurement:

- Continuous distance measurement

- Analog current or voltage output

- Distance changes are tracked in real time

- Ideal for level measurement, positioning, and range monitoring

Ranging sensors are used when exact distance or level information is required rather than simple presence detection. For outdoor applications or other areas with large temperature variations consider using models with temperature compensation.

Installation and Performance Considerations

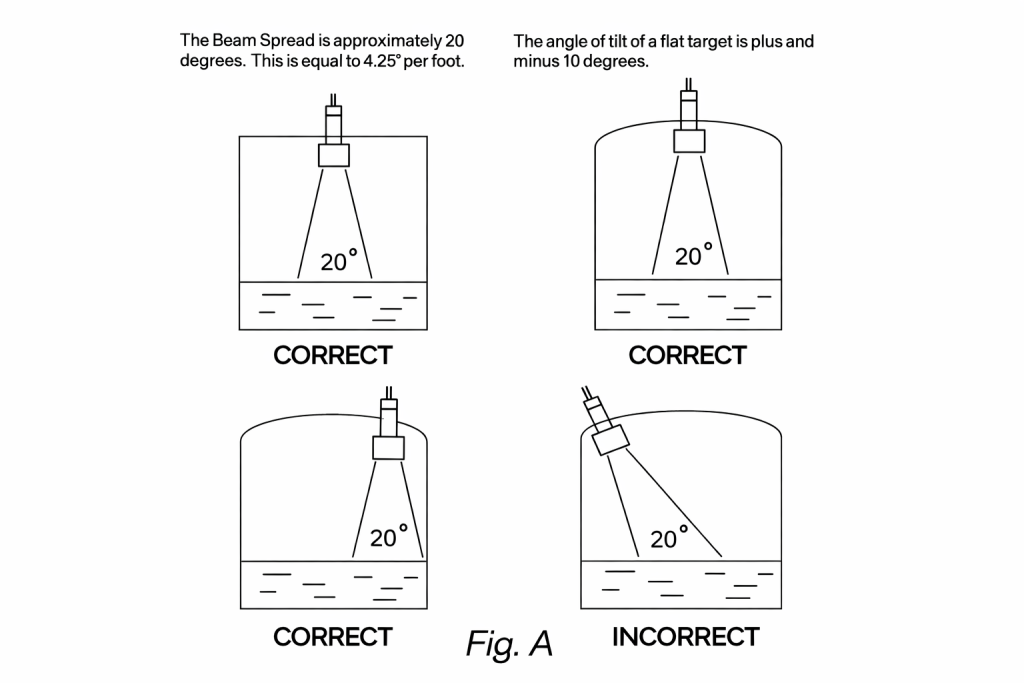

Proper installation is critical to ultrasonic sensor performance. Beam spread and target angle must be taken into account when mounting a sensor.

Beam Spread

Ultrasonic sensors emit sound in a conical pattern rather than a straight line. A typical ultrasonic sensor has a beam spread of approximately 20 degrees, which corresponds to roughly 4.25 degrees per foot of distance.

As distance increases, the beam diameter expands. Any object within this cone can reflect sound back to the sensor, including tank walls, internal structures, or mounting hardware. Proper sensor placement must account for this expanding beam to avoid unintended reflections.

Key considerations:

- Ensure sufficient clearance between the beam edge and tank walls

- Avoid mounting locations where internal obstructions fall within the beam

- Consider narrower beam sensors for confined geometries

Target Angle

Ultrasonic sensors rely on sound reflecting back toward the transducer. For flat targets, the angle of the target surface relative to the sensor is critical.

A flat target can typically tolerate a tilt of plus or minus 10 degrees and still return a usable echo. Beyond this range, reflected sound is deflected away from the sensor, resulting in signal loss or unstable readings.

As illustrated in the example:

- Sensors mounted perpendicular to the target surface provide the strongest return signal

- Slight offsets are acceptable when the target remains within the beam

- Excessive sensor tilt causes the ultrasonic energy to reflect away from the sensor, producing unreliable measurements

Other considerations include:

- Minimum sensing distance (dead band)

-Targets must remain outside the sensor’s blind zone for reliable detection. - Mounting clearance

-Avoid direct metal contact near the sensing face to prevent vibration interference. - Target surface

-Flat surfaces perpendicular to the sensor provide the strongest return signal. - False echoes

-Internal tank structures, ladders, or fittings can reflect sound back to the sensor. - Multiple sensor installations

-Synchronization lines can be used to prevent cross-talk when sensors are mounted close together. Available on RPS-409A product lines.

These factors should be evaluated during system design to ensure stable measurement. Migatron offers direct engineering support, you may contact us to assist with technical questions.

Where Ultrasonic Sensors Perform Best

Ultrasonic sensors are used in applications requiring non-contact measurement, reliable detection, and minimal maintenance. Using time-of-flight measurement, ultrasonic sensing performs well in industrial environments where other sensors are impractical or unreliable.

Key application include:

- Tank level measurement: Non-contact level measurement in tanks and vessels. Common in water, wastewater, chemical storage, and fuel applications where buildup, corrosion, or mechanical wear are concerns.

- Distance measurement: Continuous distance and position measurement for objects moving toward or away from the sensor. Used in positioning, monitoring, and verification applications.

- Process control: Stable analog feedback for roll diameter and level or distance based control loops. Integrates easily with PLCs and automation systems.

- Hazardous Areas: Level and distance measurement in hazardous locations using Intrinsically Safe Ultrasonic Sensors. Applied in agriculture, wastewater, mining, oil & gas environments.

- Production lines: Presence detection and position monitoring on conveyors and automated equipment. Reliable detection regardless of target color or surface finish.

These applications reflect where ultrasonic sensing delivers consistent performance with simple integration.

Ultrasonic Sensors Compared to Other Technologies

Ultrasonic sensors are often evaluated alongside other level and distance measurement technologies.

- Ultrasonic vs radar: Radar offers better performance through heavy vapor and foam but typically comes with higher cost and complexity. Ultrasonic sensors are simpler and cost-effective for clean air applications.

- Ultrasonic vs pressure sensors: Pressure sensors require process contact and are affected by fluid density and temperature. Ultrasonic sensors measure level directly without contacting the media.

- Ultrasonic vs mechanical floats: Floats are simple but introduce moving parts and wear points. Ultrasonic sensors eliminate mechanical contact and maintenance.

Ultrasonic sensing is best viewed as a practical solution for short-to-mid range measurement where environmental conditions are compatible.

Related Resources

Learn more about ultrasonic sensor applications, intrinsically safe ultrasonic sensors, and technical resources for tank level measurement, distance sensing, and industrial process control.