ATEX & IECEx Certified Ultrasonic Sensors

Our ATEX and IECEx approved sensors ensure compliance for operations in potentially explosive atmospheres.

ATEX & IECEx Approved Sensors for Hazardous Areas

Our comprehensive range of ATEX and IECEx approved ultrasonic sensors deliver reliable performance in hazardous areas.

Intrinsically Safe Analog Ultrasonic Sensor

Intrinsically Safe Analog Ultrasonic Sensor

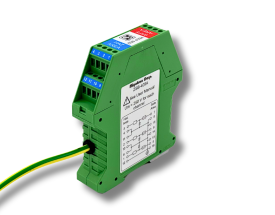

Intrinsically Safe Barrier

Intrinsic Safety Protection

Migatron’s certified sensors utilize intrinsic safety protection methods to eliminate ignition risks in hazardous areas. This approach ensures that electrical energy in the sensor circuit remains below levels that could cause ignition of the surrounding explosive atmosphere.

Key Safety Features:

- Energy Limitation: Electrical and thermal energy restricted below ignition thresholds

- Robust Construction: Durable housings designed for industrial environments

- Isolation Barriers: Integrated protection to limit voltage and current to the hazardous area

Protection Level Ex ia

Migatron’s ATEX and IECEx certified sensors provide the highest level of Intrinsic Safety protection.

With an Ma equipment protection level the sensors can remain energized and operational in mines with firedamp and/or coal dust.

With a Ga equipment protection level the sensors can be used in Zones 0, 1 and 2 for gases, vapors and mists.

With a Da equipment protection level the sensors can be used in Zones 20, 21 and 22 for combustible dusts.

Expert Guidance for Hazardous Area Applications

With decades of experience in developing certified sensors for hazardous areas, Migatron’s engineering team provides expert consultation to help you select the right certified sensor for your specific application requirements.

Critical Applications in Hazardous Areas

ATEX and IECEx certified sensors are essential in numerous applications where explosive atmospheres are or may be present:

Storage tank level monitoring

Processing equipment monitoring

Reactor vessel monitoring

Storage tank level control

Fuel storage monitoring

Material level detection