Ultrasonic Tank Level Sensors

Designed for Liquid Level Measurement in Tanks

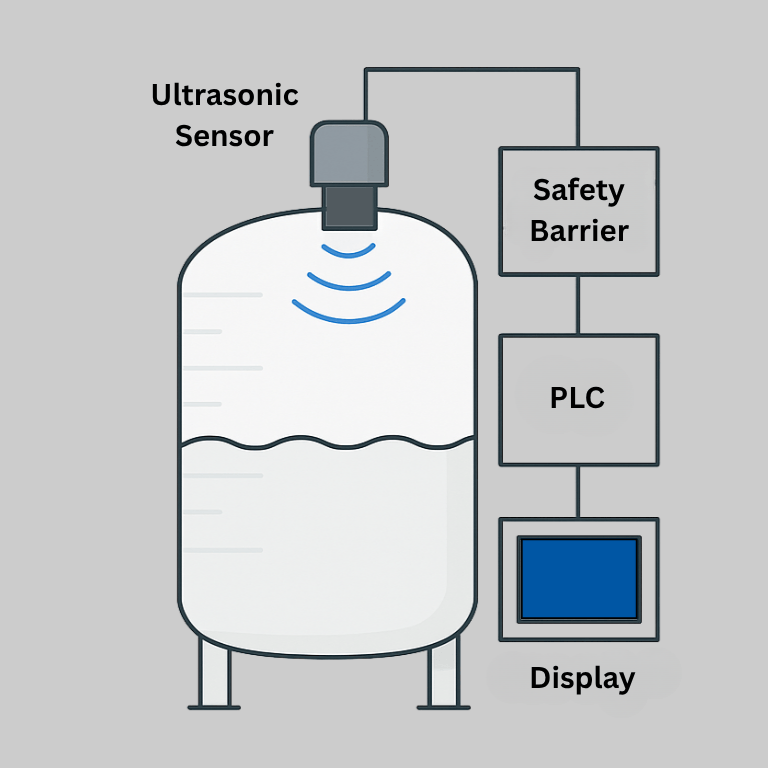

Tanks often use industrial sensors for continuous level monitoring and measurement, which must be accurate and reliable. Whether you’re monitoring production tanks, separators, chemical storage, or water treatment vessels, Migatron’s ultrasonic sensors provide a proven solution. Our sensors enable non-contact level sensing across a wide range of tank materials and sizes, helping operators reduce downtime and automate inventory management, even in Hazardous Locations or Explosive Atmospheres when using Intriniscally Safe models.

Whether you need sensors for packaging machines or a sensor for part positioning, Migatron offers the best non-contact sensors for factory automation. Our non-contact sensors ensure that even irregular or transparent surfaces can be reliably detected, eliminating common production bottlenecks.

Built for Demanding Applications

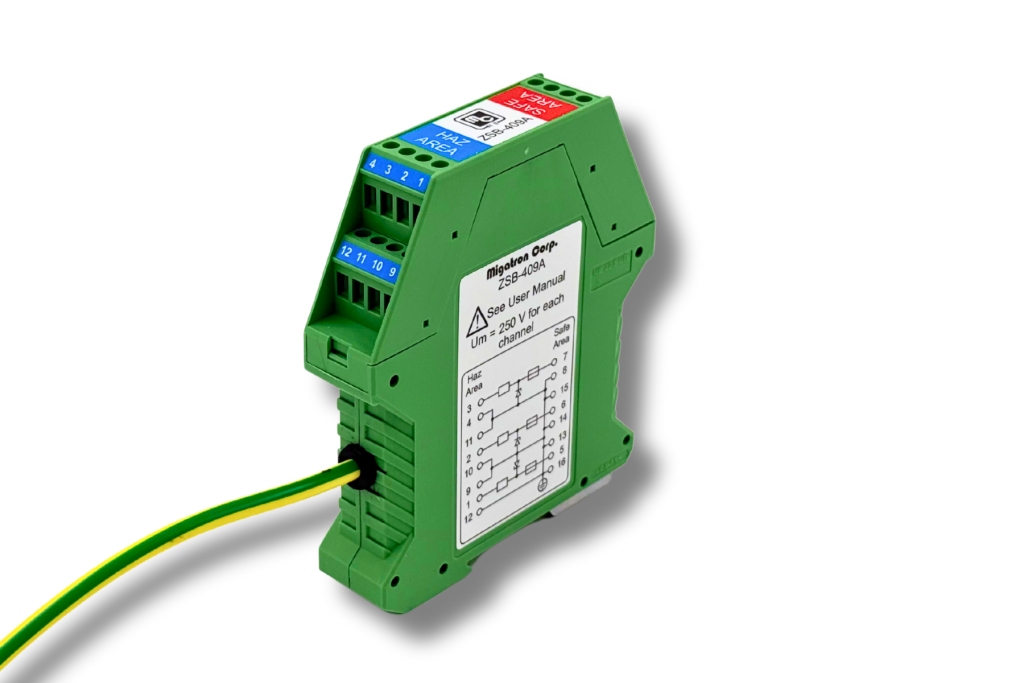

Hazardous Locations Approved

Our Intrinsically Safe Ultrasonic Sensors are certified for use in hazardous gas or dust environments classified as Zone 0, 1, 2, 20, 21, or 22 for ATEX/IECEx, and Class I, II, or III for C-UL-US when used with approved intrinsic safety barrier(s). They’re engineered to perform in flammable gas and vapor environments typical in upstream, midstream, and downstream oil & gas operations.

Non-Contact Measurement

No moving parts. No contact with the liquid. Migatron sensors use ultrasonic sound waves to deliver precise level readings without risk of corrosion, buildup, or mechanical wear.

All Tank Types

Whether installed on steel API tanks, plastic totes, or fiberglass vessels, our ultrasonic tank level sensors adapt to your setup. With adjustable sensing ranges and analog outputs, they work across varied heights and diameters, even with sloped or domed tank tops.

Outdoor Use

Designed for use in exposed locations, our sensors operate reliably in wide temperature ranges, high humidity, and dusty or corrosive environments. Many models are fully sealed and IP67-rated for added protection

Featured Intrinsically Safe Ultrasonic Sensors

Proven Sensor Technology for Safe Tank Monitoring

Migatron’s ultrasonic sensors are trusted in automation, level monitoring, and SCADA integration throughout the oil & gas sector. Our ultrasonic tank level sensors are easy to install, require minimal maintenance, and deliver years of reliable service.

- Crude Oil Storage Tanks

- Diesel Fuel & Oil Monitoring

- Towing Tanks

- Separator & Treater Vessels

- Diesel and Fuel Storage

- Lubricant Oil Tank Monitoring

- Ingredient Fluid Level Detection

See How Our Ultrasonic Sensors Solve Real-World Challenges

Level Control For Caustic Liquids

See how Migatron sensors are used for monitoring the liquid level of a warm acid bath and provide a continual status report to process control.