When it comes to selecting an ultrasonic sensor for your application, beam spread is one of the most overlooked yet critical performance characteristics. Whether you’re designing a system for tank level monitoring in hazardous locations or managing material flow on a conveyor belt system, understanding how a sensor’s beam behaves helps ensure accuracy, repeatability and reliability.

What Is Beam Spread?

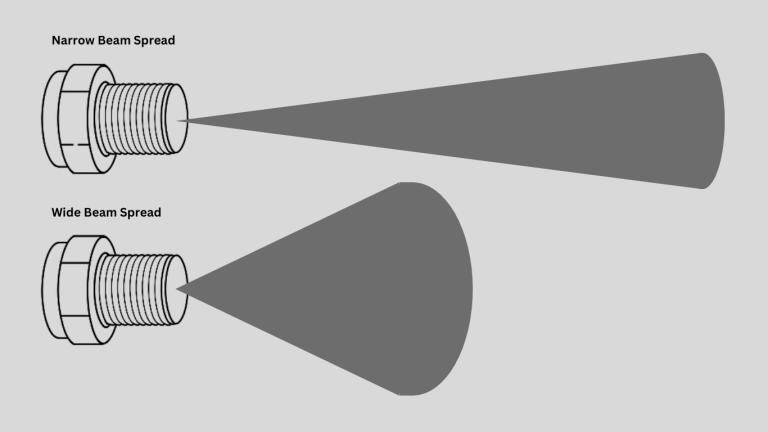

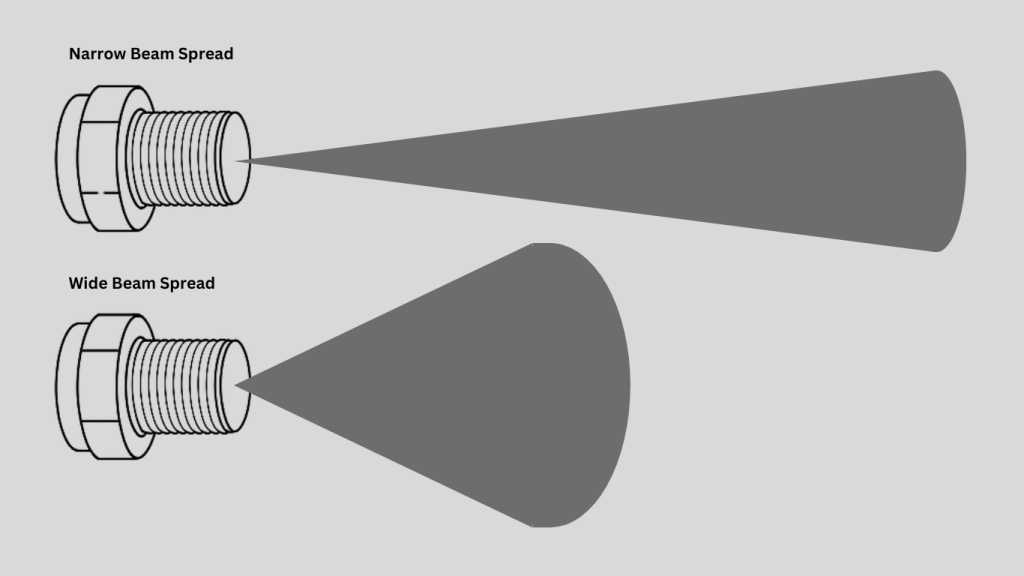

Beam spread refers to how wide the ultrasonic sound wave becomes as it travels away from the sensor face. Think of it like the beam of a flashlight—the further it travels, the more it diverges. In ultrasonic sensing, this “spread” determines not only how much area the sensor covers but also how it interacts with different target sizes and shapes.

Why Beam Pattern Visualization Matters

Beam patterns aren’t just theoretical—they’re measurable. At Migatron, we test beam patterns using different target types:

- A: 4″ x 4″ flat plate

- B: 3″ diameter rod

- C: 0.625″ diameter rod

These targets simulate different application environments such as flat tank walls to narrow pipes. This helps engineers understand detection thresholds based on reflectivity and geometry.

Here’s an example from our RPS-409A-IS3 sensor line. When operating at longer ranges (up to 216 inches), the beam expands significantly, which is ideal for level sensing in open tanks. But for precision detection of smaller targets, the tighter beam of a short-range model (e.g., the 40″ version) offers better spatial resolution.

How Target Angle Affects Detection

Target angle refers to the maximum angle of tilt a sensor can tolerate while still reliably detecting an object. Because ultrasonic waves rely on echo reflection, performance is highest when the target surface is perpendicular to the sensor face. As the angle increases, reflected sound may miss the transducer entirely, leading to weak or inconsistent readings.

Each sensor has a defined tilt response limit, which varies based on beam spread and sensitivity. For example, the Migatron RPS-150 can detect flat targets tilted up to 35 degrees, making it ideal for irregular or moving surfaces.

When an application involves tilt beyond the capability of a single sensor—such as angled packaging lines, curved tanks, or vibrating panels—multiple sensors can be teamed to cover a wider angular range and ensure reliable detection across the full surface profile.

For critical measurements, always consider both:

- Beam geometry, which defines how broad or narrow the sensor’s coverage is.

- Target orientation, which defines how much tilt the sensor can accommodate.

Selecting the right combination will improve detection accuracy and minimize the risk of false negatives in fast moving environments.

Application Engineering Tip: Use Beam Spread to Your Advantage

- Narrow Beams are ideal for detecting small or closely spaced objects without interference. Sensors like the RPS-400-30 with its narrow beam and short-range analog output, are often used in positioning applications on conveyor lines.

- Wider Beams help in open-area detection or bulk material applications where the surface may not always be perpendicular to the sensor. For example, the RPS-4000 with its 2-40 inch range excels in large tank monitoring.

- Hazardous Location Considerations: In hazardous locations and explosive atmospheres, both the RPS-409A-IS2 and RPS-409A-IS3 are intrinsically safe and feature temperature compensation to keep readings accurate despite environmental variability.

Key Takeaways for OEMs and Engineers

- Don’t just look at sensor range, understand the beam width and shape.

- Match the beam to the target size, target angle, and mounting constraints.

- Use beam diagrams to determine the sensor’s ability to detect your specific target.

- In multi-sensor arrays, consider cross-talk and use Sync/Tx lines where available to coordinate emissions.

Final Thought

Beam spread isn’t just a specification—it’s a design parameter. If you’re engineering systems for material handling, liquid level monitoring, or object detection, choosing the right beam profile is just as important as choosing the right output or approval.

Migatron’s Intrinsically Safe Ultrasonic Sensors offer various beam patterns to meet the demands of high-precision, industrial automation, and Intrinsically Safe applications. Want help selecting an ultrasonic sensor? Our Engineering team is here to assist.