Ultrasonic Sensors for Mining Equipment

Accurate, reliable, and precision ultrasonic sensing solutions that work.

Hazardous Location Ultrasonic Sensors for Mining

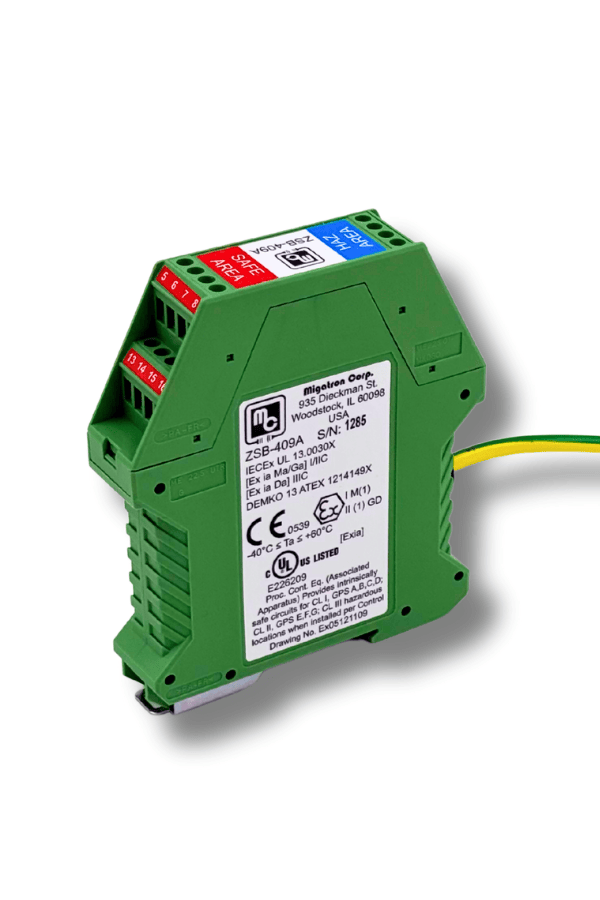

Migatron’s intrinsically safe ultrasonic sensors are tested and approved to meet Ex ia Ma protection level for equipment used in underground coal mines and related surface facilities. This approval ensures that our sensors remain operational in explosive atmospheres that may contain firedamp (methane gas) and coal dust clouds under normal mine conditions (0.8 to 1.1 bar pressure, -20°C to +60°C).

This protection level confirms that properly designed intrinsically safe ‘ia’ circuits, such as those used in our sensors, are inherently safe even in atmospheres with a significantly higher ignition energy threshold—like those involving coal dust.

Mining Equipment for Hazardous Environments

If you’re building machinery that must operate in areas exposed to firedamp or coal dust, selecting the right sensor is critical. Migatron’s sensors are engineered to function in mines, with the approvals you need.

Ultrasonic Sensors for Mining Equipment

Conveyor Belt Alignment and Tracking

Featured Intrinsically Safe Sensor: RPS-409A-40P-MSHA

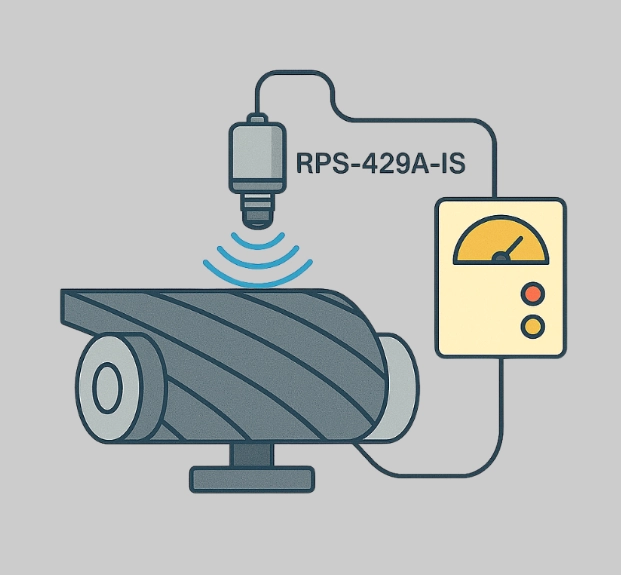

In the mining industry, conveyor belt alignment is essential to maintaining efficiency, but misalignment can cause spillage, equipment wear, and downtime. For operations in firedamp and coal dust prone environments, OEMs and mining engineers require sensing technology that remains functional under hazardous conditions.

How It Works

- The ultrasonic sensor is mounted overhead, near the belt’s edge

- Continuously measures belt position using ultrasonic pulses

- Transmits analog output to PLC

- Enables real-time correction to reduce belt drift, wear, and unplanned stoppages

Why RPS-409A-40P-MSHA

- Analog output for easy integration with alignment control systems

- Durable PVC housing and IP-rated construction for harsh mining environments

Ultrasonic Sensor Applications in Mining

Our line of intrinsically safe ultrasonic sensors are engineered to perform reliably in the high risk environments found in underground and surface mining operations. Whether you’re monitoring conveyor belt alignment or deploying collision detection systems, Migatron sensors deliver accurate, non-contact distance measurement with approvals for use in firedamp conditions found in mines.

Let’s Talk Sensors for Mining

Looking for a sensor supplier that understands mining safety standards and OEM integration?

Migatron’s intrinsically safe ultrasonic sensors are built to meet the rigorous demands of Group I, Category M1 mining environments, including firedamp and coal dust. Our sensors are engineered to remain functional in the harshest conditions.

Contact us today to discuss how Migatron can support your next mining equipment project.

- Phone: (815) 338-5800

- Email: info@migatron.com

- Web: migatron.com